Foot

Surgery (A happy accident):

I had just returned my 1:100 Altron to its

shelf above my wife’s dresser. It was

still in an action pose (essentially same as the photo to the  right),

which meant it was a bit off balance. I

thought I had it tilted so if disturbed, it would fall back against the

wall instead of taking a header off the shelf.

I was wrong. When I came back

later that day,

right),

which meant it was a bit off balance. I

thought I had it tilted so if disturbed, it would fall back against the

wall instead of taking a header off the shelf.

I was wrong. When I came back

later that day,  Altron

was in several pieces on the dresser. I

immediately rushed it to my “emergency” room, and began to clean up the

(thankfully) minor paint damage. While

it was apart, I decided to make a mod I had been planning on for some time, and

one I had picked up from a B-Club conversion—double ball ankle joints. The cause of the fall was due in part to

the floppy knee joints Altron suffers from and also to the lack of good foot

balance. As can be seen, the left foot

is barely in contact with the ground—only the inside edge of the foot is

keeping this guy up. Even with the

offset ball joint on the foot, ankle mobility is not good. The kit is indeed leaning backwards in this

photo, just to keep from pitching over into a face plant. I had ordered some Kotobukiya #111B double

ball joints from HLJ

a month ago, and figured now was a good time to use them.

Altron

was in several pieces on the dresser. I

immediately rushed it to my “emergency” room, and began to clean up the

(thankfully) minor paint damage. While

it was apart, I decided to make a mod I had been planning on for some time, and

one I had picked up from a B-Club conversion—double ball ankle joints. The cause of the fall was due in part to

the floppy knee joints Altron suffers from and also to the lack of good foot

balance. As can be seen, the left foot

is barely in contact with the ground—only the inside edge of the foot is

keeping this guy up. Even with the

offset ball joint on the foot, ankle mobility is not good. The kit is indeed leaning backwards in this

photo, just to keep from pitching over into a face plant. I had ordered some Kotobukiya #111B double

ball joints from HLJ

a month ago, and figured now was a good time to use them.

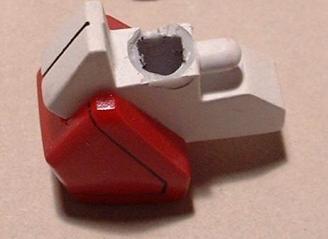

The mod plan was

simple—cut off the ball joint on the foot, add a ball socket, then reattach the

foot to the kit with a double ball joint (left), using the existing ball socket

in Altron’s lower leg. I started by

clipping off the foot ball, and then drilling it out with progressively larger

drill bits.  I wanted the hole to be large enough to

slightly countersink the socket. If you

want to bury the cup even deeper into the foot to keep the same height, it

wouldn’t be a problem. But since this

kit was already painted and finished, I didn’t want to take too many chances

with the paint on the foot sides.

I wanted the hole to be large enough to

slightly countersink the socket. If you

want to bury the cup even deeper into the foot to keep the same height, it

wouldn’t be a problem. But since this

kit was already painted and finished, I didn’t want to take too many chances

with the paint on the foot sides.

The next step was to

attach the cup portion of the ball joint to the foot. The Kotobukiya joints are made of ABS plastic, which like the

Bandai PV caps, can’t be glued well to styrene. To fix the cup, I needed an anchor to mechanically hold it in

place whether the  glue

worked

or not. Using my trusty lighter, I

slightly singed the end peg and smooshed it into a shape that would give me the

anchor needed. I then completely filled

the interior of the heel section with superglue/talcum powder (SGT). After putting the cup in anchor down, the

SGT will completely fill in around the anchor, totally locking the joint in

place.

glue

worked

or not. Using my trusty lighter, I

slightly singed the end peg and smooshed it into a shape that would give me the

anchor needed. I then completely filled

the interior of the heel section with superglue/talcum powder (SGT). After putting the cup in anchor down, the

SGT will completely fill in around the anchor, totally locking the joint in

place.

There were two major

problems remaining: The Kotobukiya

double ball joint is too loose in the Bandai ankle socket, and the double ball

joint is too tall, which would give Altron a very exposed, odd looking

ankle. To get around that, I

scratchbuilt my own double ball joints.

The first step was to completely fill the kit ankle joint cup with

SGT. Since the kit cup is PV, it acts

as a mold for the SGT, which I took out 10 minutes later. One trick here for strength and ease

debonding: put a wooden toothpick into

the SGT as it is setting up. This gives

you something to grab to help pull it out, but also gives the SGT a bit of

strength. The toothpick was trimmed

down to as long as I wanted the foot side ball to be and then stuck into

the111B joint cup filled with liquid SGT.

When  the

SGT is dried, you have a complete, well bonded, and tough double ball

joint. The homemade double ball joint

was carved and sanded into a figure 8 so it could give better flexing. The finished homemade joint and the original

joint are shown side by side for comparison.

You may find that using the joint cup for a ball joint

the

SGT is dried, you have a complete, well bonded, and tough double ball

joint. The homemade double ball joint

was carved and sanded into a figure 8 so it could give better flexing. The finished homemade joint and the original

joint are shown side by side for comparison.

You may find that using the joint cup for a ball joint  master

mold gives you a slightly loose joint—the ball should actually be a little

bigger than the size of the cup. A

quick fix is to apply clear nail polish to the ball until it is sufficiently

tight. A longer term fix is to take the

ball and spray a ton of paint (in multiple coats!) on it, building up the size

of the ball. You can then make RTV

molds and resin copies of the joint.

Either way works. The finished

foot is shown to the right (make sure to put the slightly smaller ball into the

foot side cup—test fit on the leg side first).

There was minimal visible damage to the foot from the drilling, which is

easy to touch up, but also covered by the lower leg. Now the whole unit can be plugged back into the lower leg.

master

mold gives you a slightly loose joint—the ball should actually be a little

bigger than the size of the cup. A

quick fix is to apply clear nail polish to the ball until it is sufficiently

tight. A longer term fix is to take the

ball and spray a ton of paint (in multiple coats!) on it, building up the size

of the ball. You can then make RTV

molds and resin copies of the joint.

Either way works. The finished

foot is shown to the right (make sure to put the slightly smaller ball into the

foot side cup—test fit on the leg side first).

There was minimal visible damage to the foot from the drilling, which is

easy to touch up, but also covered by the lower leg. Now the whole unit can be plugged back into the lower leg.

Results!

Comparing the original to modified foot in a

normal pose. Modified ankle on right;

the new ball joint adds about 1-2 mm of height to the leg, depending on how it

is posed.

This

photo shows the original and modified leg at maximum side deflection. In both cases, the feet are flat on the

ground, and the heels are aligned. The

toothpicks were required to keep the new foot/leg from toppling over.

Original to new ankle posing (similar poses); note how much better the modified feet plant.

Modified

Altron Gallery (a selection of poses. > 100 kb):

Pose 1 Pose 2 Pose 3 Pose 4 Pose 5